Results 1 to 20 of 39

-

11-06-2014, 02:42 PM #1

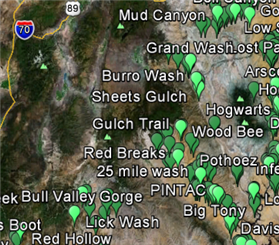

HOW STRONG IS THAT SLING? or ARE YOU GONNA RAP ON THAT!!!???

Been thinking about some sling testing for a while, but it was BOUNDARY with Artur, Kate, and Desi that brought it all to a head.

The second rappel, and Artur (who is fast!) took one look at the anchor, set the rope and was poised at the edge before I took a second look.

Whoooaaaaa there, brother are you gonna rap on THAT??!!!

Artur and Kate at the Rappel in question.

The anchor was a semi-manky blue sling wrapped around a largish boulder and choked to itself then extended single strand about 15 feet over a log to the edge of the drop.

But it was not the general set up that was freaking me out.

It was a ding in the sling where it had rubbed on a edge of the boulder:

Here is a close up:

But Artur, an "old-hand" at Death Valley single strand web anchors says "no problem", and he is outta there.

So I quietly put on a meat back up for the crew, then replaced the anchor and brought the funky stuff home...

-

11-06-2014 02:42 PM # ADS

-

11-06-2014, 02:47 PM #2

Shhhhhiiiiittttt..... that webbing is almost brand new compared to some of the stuff we rap on....

-

Post Thanks / Like - 4 Likes

-

11-06-2014, 03:08 PM #3

Sample slings ready for testing

Well, how strong is that sling?

to answer the question in a meaningful way, it is helpful to establish a "baseline" of how strong brand new sling starts out- and then goes down hill with age, wear, and damage.

Our little experiment is just semi- scientific. Without controls over all the crazy stuff that happens to slings in the canyons it is hard to know when a particular sling is due for the garbage can- but we can at least get some idea by BUSTING some new slings and then some funky slings.

FUN, huh!

the TEST RIG:

We start with two sets of slings, three samples each:

The first set of three is bright orange color MIL-SPEC (5625) one inch tubular denoted by a single black tracer thread in the center.

And no, I would never use this hideous orange color in a canyon- hence the sacrifice to the testing gods.

These slings are tied in a loop with the classic "water knot" and placed on our test rig over two big fat smooth shackles and pulled slowly till they pop.

We are breaking three identical slings from the same spool to see how much variation there may be from little inconsistencies in the knot, the web, etc.

The next set of three, tied the SAME way are three pieces of tan color BlueWater one inch tubular slings.

After that, we are breaking two MORE sets of three, this time tied SINGLE STRAND (with over-hand loops tied in both ends) to see what happens as we go from loop to single.

-

11-06-2014, 03:35 PM #4

Whoops posting malfunction-

typical loop sling break results:

Here are the numbers:

LOOP TEST tied with water knot breaking strength in LBS

BlueWater

6160 lbs

6300 lbs

5480 lbs

Mil-spec

5940 lbs

5460 lbs

5960 lbs

Any smart person who wants to do a 3-Sigma is most welcome!

SINGLE STRAND TEST with overhand loops in ends (in LBS)

BlueWater

2400 lbs

2880 lbs

2580 lbs

Mil-spec

2740 lbs

2840 lbs

2720 lbs

-

Post Thanks / Like - 2 Likes

-

11-06-2014, 04:22 PM #5

Assuming its linear and about 25% of the webbing is cut, that blue strand in the first post shouldn't break less than 1800 lbf.

This is great thanks for doing this! Results will be interesting.

Are you planning on any testing due to UV degradation?

-

Post Thanks / Like - 1 Likes

harness man liked this post

harness man liked this post

-

11-06-2014, 09:41 PM #6

-

Post Thanks / Like - 1 Likes

harness man liked this post

harness man liked this post

-

11-06-2014, 10:38 PM #7

Oh snap.... another engineering battle!

Life is Good

Life is Good

-

Post Thanks / Like - 1 Likes

harness man liked this post

harness man liked this post

-

11-06-2014, 10:45 PM #8

-

Post Thanks / Like - 1 Likes

harness man liked this post

harness man liked this post

-

11-07-2014, 01:27 AM #9

Yes, 99.9% of the webbing we rap on is nylon.

-

Post Thanks / Like - 1 Likes

harness man liked this post

harness man liked this post

-

11-07-2014, 07:27 AM #10

Yes, Nylon.

The reason it is not linear (ie, strength proportionate to the intact number of fibers) is that integrity counts. When the webbing is intact, the stress distributes well across the fibers. Cut a bundle of fibers or two, and now you have a stress concentrator, and the strength goes down quickly with that first cut.

How much?

Hard to say.

An analogy would be - take a strip of paper. Intact - pull on it and it will not break (to a point). Put a short cut in one side, and it breaks easily. One would say that this system has NO toughness. Your nylon webbing will have considerably more toughness, but...

Tom

-

Post Thanks / Like - 2 Likes

-

11-07-2014, 08:04 AM #11

To Tom's point, I for one get very spooked by any dings in anchor slings- hence the concern over the boundary sling.

So what to take away from testing so far?

1. note the range of test results for identical slings. In general, a lot of variation in test results is BAD- it means you have changes in the raw material or process that you are NOT controlling for- in this case it is largely due to the knots.

Each water knot is slightly unique and crushes down on itself just a little differently each time.

Heat is a factor in the failure point at the knots- all ruptured ends have some melting.

2. SINGLE STRAND is WAY DIFFERENT than a loop of sling.

Depending on how you rig a loop sling around a tree, rock, or pinch- the knot (weakest point) can sometimes be protected to improve the overall strength. Of course, there are dumb ways to rig loop slings to decrease the strength (more on that later).

But with a single strand sling terminated to a quick link with and overhand knot, 2,400 lbs (our lowest test value) is the BEST you ever get! And things go down hill from there.

So here is what happened to the blue Boundary sling- along with the damaged bit of webbing there was also a SPLICE in the web nearby- too close to cut out of the test strand - so it became part of the test- and guess where the sling broke?

So the scary damaged bit survived but the sling broke instead at the knot where the sling was extended.

Now some will say, 1,480 lbs is not bad... but it is a WAYS down from 2,400 lbs (new sling)

So how do you know when to replace a sling?

-

Post Thanks / Like - 1 Likes

ratagonia liked this post

ratagonia liked this post

-

11-07-2014, 08:23 AM #12

OK cool, that makes sense. I did not think there would be much notch sensitivity with a bundle of woven fibers. My thinking along with your example was that if we had the same piece of paper but cut into strips. Cut a couple strips and the breaking strength would be proportional. But yea it all matters how that load is now distributed from those cut bundles to the intact bundles.

-

Post Thanks / Like - 1 Likes

harness man liked this post

harness man liked this post

-

11-07-2014, 08:44 AM #13

Just ran a couple of tests with SPLICES in (new) single strand 1" tubular.

Breaking in the same range as the overhand terminations in new 1" tubular single strand: 2,400 lbs.

So no unexpected loss there, but another weak link in the chain, so to speak.

-

11-07-2014, 08:47 AM #14

Good post. Very nice, informative work, harness man.

-

Post Thanks / Like - 1 Likes

harness man liked this post

harness man liked this post

-

11-07-2014, 09:03 AM #15

Thanks

Now that we have a handle on some new sling values, we can let 'er rip on a bunch of old stuff!

Tom and Skunkteeth have raised the question of how much of the linear strength of the webbing is affected by a partial cross-cut?

THAT is an intriguing question....

The tubular webbing types we have been testing are engineered primarily for tensile strength but there are other important properties also.

One difference between the BlueWater and the Mil-spec is that while the tensile strength is similair the BW is designed to be more abrasion and cut resistant: more canyon-friendly?

More testing to come....

-

11-07-2014, 09:21 AM #16

-

Post Thanks / Like - 1 Likes

nkanarik liked this post

nkanarik liked this post

-

11-07-2014, 09:39 AM #17

"One difference between the BlueWater and the Mil-spec is that while the tensile strength is similair the BW is designed to be more abrasion and cut resistant: more canyon-friendly?"

That's what they SAY, however, a lot of that may be marketing razzle-dazzle.

The BW climb-spec webbing is really nice webbing. One nice thing about it is that it is made by a reputable company under tight QC conditions, so it will perform at a consistent high level. It is heavier than the mil spec stuff, and tends to be considerably stronger, in the range of 6000 lbs, single strand.

The "Mil-spec" stuff, on the other hand, does not necessarily even make the mil spec. It is made in various mills by various players, and varies widely in how it comes out. The minimum strength on that stuff is probably 4000 lbs. I've seen some that I suspected would not even reach that. However, I don't see stuff that is so bad as to be "not safe", very often.

I buy "Mil-spec" webbing from a reliable vendor in California, and have confidence in the stuff I sell. But... it is not clear why I have that level of confidence, other than this particular vendor has been selling webbing to climbing shops for at least 30 years (yikes, have I been buying webbing from them that long???!). Does it meet the mil-spec - I don't know.

I've got some samples made up, some of them uv-d out. Maybe I should send those to Mr. Harness Man for testing?

Tom

-

11-07-2014, 12:01 PM #18

clarification of splice in the middle of single strand sling

Hi Tom

uv-d samples would be great!

Do you have any details on the history of the sling?

I think you have our address- plus I need to order those new poly/rubber gloves of yours- they are much better...

I am also not sure that the BW web is better in the canyons. And thanks for the exposition on Mil-spec: lots of x-plainin'

The mil-spec used for this test did very well!

We have some history with the BW tubular-we developed a proprietary buckle especially for one inch tubular- and the BW web yields the highest breaking strength when threaded thru our buckle.

Mil-spec is breaking about 10% lower in the buckle application.

So now we are kind of wondering

How strong is our box of faded/crunchy/sandy/frayed slings from the canyons?

Probably have to wait till mon or tues....the weekend is nigh

Best

Todd and Desi

-

11-07-2014, 12:24 PM #19

What size gloves you wanting? The new ones are about 1/2 size larger than the old ones, so I changed from a Large to a Medium. (at least, I hope it was that!) I think I can sponsor you and Desi with a pair of gloves or two.

I tied some samples, then hung half of them out on my garage wall for most of a year, so they are well-UV's. Gotta take pics before I send them off to you... Will get those out next week.

Tom

-

Post Thanks / Like - 1 Likes

harness man liked this post

harness man liked this post

-

11-07-2014, 01:29 PM #20

Wow, thanks!

Large for me and Desi has munchkin fingers: x-small (if they come in that size).

Hanging on the wall for a year in the sun: perfectly controlled group for UV'd web sample .

.

Best, Todd and Desi

Similar Threads

-

[Help] Sling taken from Not Tierdrop Canyon on 6/3/11

By summitseeker in forum CanyoneeringReplies: 9Last Post: 06-08-2011, 08:10 AM -

Omni Sling

By moab mark in forum CanyoneeringReplies: 38Last Post: 05-10-2010, 11:44 AM -

Documentary: Strong views on Utah wilderness

By stefan in forum Environmental IssuesReplies: 33Last Post: 02-28-2010, 06:02 PM -

[Trip Report] Rainbow Gardens to Strong Canyon - TR

By Sombeech in forum Mountain Biking & CyclingReplies: 9Last Post: 05-13-2008, 08:39 PM -

THE PIMP IS BACK AND PIMPIN STRONG!

By MY T PIMP in forum General DiscussionReplies: 6Last Post: 06-19-2007, 06:39 AM

Visitors found this page by searching for:

Outdoor Forum

Reply With Quote

Reply With Quote