Results 1 to 15 of 15

Thread: New Bolts in Uturn

-

10-18-2010, 12:32 PM #1

New Bolts in Uturn

We Visited UTURN in Arches NP this last weekend. The last time we were there we did the last rap from natural anchors at the crack. This time around we were surprised to find bolts next to a very large rock. This rappel is maybe 50 yards down along the ridge from the original crack rappel. The rope grooves at this rappel are extensive. I still think the crack rappel is the way to go here. There is an abundance of natural anchors and the grooving after so many years of use is minor.

Don't believe everything you think.

-Borrowed from a bumper sticker I believe

-

10-18-2010 12:32 PM # ADS

-

10-18-2010, 03:47 PM #2

Do you have a close up pic of the bolts?

-

10-18-2010, 04:21 PM #3

Those new bolts have been there for at least a year.

-

10-18-2010, 04:25 PM #4

I could be getting confused with the last rappell in Tierdrop, but I am pretty sure they were there in Oct last year.

-

10-18-2010, 04:51 PM #5

We didn't notice any bolts at the last rap in Tierdrop.

-

10-18-2010, 05:23 PM #6

Did you notice if the bolts had white silicone/epoxy around them?

-

10-19-2010, 11:14 AM #7

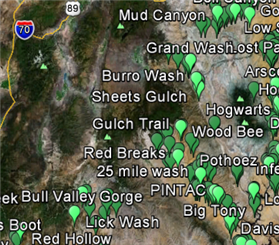

-

10-19-2010, 01:31 PM #8

Those bolts were NOT there in the spring, I removed all "optional" rappels this spring trying to keep canyoneering flying under the parks radar as much as possible while the NP is writing their new management plan.

Anyhoo.... when I see new bolts like this I just scratch my head. U-Turn is a popular route. It has probably been done by several thousand people from all skill levels ranging from complete noob to god like.... from kids as young as 5 to grandpa in his 70's.... so why in the world does someone think they need to place new bolts and relocate the rappel?

FWIW: A couple of the Arches rangers have recommended we keep the final U-Turn rappel out of view from the Park Avenue tourists. Everyone's help in honoring that recommendation is appreciated. Please use "the crack" rappel.

-

10-19-2010, 01:40 PM #9

-

10-19-2010, 02:56 PM #10

-1 for the wonton bolting. i reckon i'd better visit the Arches canyoning routes (very) soon before the new management plan restricts and/or closes access.

-

10-20-2010, 12:37 PM #11

-

10-20-2010, 02:29 PM #12

I'm curious - what would one need to safely remove bolts like this in an aesthetically/environmentally pleasing manner?

Never having placed a bolt myself, could they be wrenched out? Or would you need to drive a wedge underneath and pop them out? Or cut them off flush with the rock?

And for filling/obscuring the holes, some epoxy mixed with sand/grit from the area?

-

10-20-2010, 03:01 PM #13

Well, since you asked...

The method depends on the type of bolt used.

A. Powers Powerbolt - characterized by a bolthead showing: easy, unscrew the bolt (might require a large wrench or cheater stick). Pick out as many pieces as possible. Fill with epoxy putty, and smooth over with a wet trowel. Shake local sand over the top and attempt to push onto the surface without messing it up. I have had good luck making these unnoticeable, running about 70% over the last few years.

B. Hard-rock bolt/stud and/or Powers powerstud: characterized by a stud sticking out of the rock with a nut on it. Powers powerstuds are made from a lowish grade of steel, and can be cut flush (with hacksaw or small chisel), then tapped in about 1/4" and filled with putty. But other brands used for rockclimbing (especially in Limestone or Granite) are a high-quality steel or stainless steel and do not cut with a reasonable effort (the type shown in the picture looks like Stainless Steel, of which there are some of this same kind in Mystery Canyon). Perhaps with a really big wrench, one could spin it all the way out, but usually the thread don't go all that far, so that would just make the stud stick out further. I have had not much luck with these. The best I can offer is to remove the nut and hanger and then tap the stud IN as far as it will go (usually 1/4", so that 1/4" to 3/8" is still sticking out), then build a pimple of epoxy over it and cover the surface with local sand, making something that does not look TOO unnatural.

C. Glue ins I hear can be spun out with a LONG bar. Heating with a propane torch might make that easier.

Putting bolts IN or taking them out, in Sandstone, is tricky business. The stone is very fragile, and it is easy to make a bigger mess. Sometimes it is just best to remove the webbing and leave the bolts. Or, maybe in this case, remove the webbing, nuts and hangers and just leave the (largely unnoticeable) studs. For instance, putting a big crowbar on it and trying to lever it out will likely make a big scar on the rock. OK, place a sheet of plastic under it... etc. There are things you can do - but really, you can remove 90% of the unsightliness with nothing more than an adjustable wrench.

Tom

-

10-21-2010, 08:50 AM #14

A better closeup of the bolt might reveal the type better. Its some type of stud and not a Powerbolt (as Tom has pointed out).

Powerstuds in non-stainless are 1018 carbon steel, which, is fairly soft. The stainless versions are 304. Also a tad soft. Both are fairly easy to snap off after removing the hanger. Couple of very hard, well placed blows from a hammer will usually snap the stud off flush with the rock. You can tell whether or not the stud is either a Powers, Simpson, Hilti, Redhead, etc, by looking to see if there's a letter (indicating the length of the stud) on the end tip of the stud. This can be hard to see as placement into the hole with a hammer sometimes smears this but usually, you can kind of see it.

Another fairly easy method of removal for these softer, less expensive studs, is to get a longer wrench on them and just over torque them until they break. Fairly easy to do, but, please don't go down this road unless you're prepared to finish the job. Leaving an overtorqued and super weak time bomb that fails on someone could be fatal for them.

The studs in the photo's look like a climbing anchor. Most likely a Fixe but could be a Raumer. They commonly don't have a length designation on the end, and, the nut is usually a fair bit bigger than on similar sized studs. The stricking surface is fairly distinctive too. I've removed a hanger from one, and, with a fairly hard hammer strike, they'll bust off flush too. They're a fair bit burlier bolt, and, fairly expensive compared to much, much cheaper Powerbolts.

The easy thing to do for clean up, is, to just carry an adjustable wrench and remove the nut, washer and hanger. To preclude a bit of the bolt war rebolting that could happen, you could just place a flat rock over the stud to hide it from view, and, voila, the impact is much reduced. That way if the placer of the bolt really wanted one there, they could just refill the studs with a hanger/nut.

Most stud holes are overdrilled. You can usually drive either the remainding busted off bit, or, the entire stud down into the hole and flush with the rock. If they were hand drilled, probably the person didn't take the time to overdrill the hole. Easy with a powerdrill (extra second or two is all).

I use JB weld for patching holes. Easy to mix, knead the two parts into a ball about the size needed for patching. Pucky up the hole. Layer of rock dust to match. Usually, JB weld is fairly dark colored so will be good for most rock types, but, that sandstone is really red. Should be plenty of dust around to match the color. Works fairly well. Over time, the dust kind of washes/wears off and you'll see the patch but it really isn't that noticable.

Cheers,

-Brian in SLC

-

10-21-2010, 09:54 AM #15

Other than the Subway, that was my first canyon and first legit rappel.

Semi-noob with more $$$ than sense trying to find a use for all that new gear?seen all good people turn their heads each day so satisfied I'm on my way...

Similar Threads

-

Bad Bolts in Rock of Ages

By Iceaxe in forum CanyoneeringReplies: 61Last Post: 05-18-2011, 08:02 AM -

Bolts versus needless risk

By qedcook in forum CanyoneeringReplies: 104Last Post: 11-22-2008, 08:01 PM -

Bolts IN and OUT in Glen Canyon

By ratagonia in forum CanyoneeringReplies: 4Last Post: 10-07-2008, 10:40 AM -

Bolts in Baptist Draw need to be pulled

By Scott P in forum CanyoneeringReplies: 9Last Post: 05-14-2008, 06:22 AM -

FYI - Lucky Charms bolts

By gwest in forum CanyoneeringReplies: 4Last Post: 10-31-2007, 05:56 PM

Visitors found this page by searching for:

Outdoor Forum

Reply With Quote

Reply With Quote